P-381 Multi-Mission Dry Dock #1

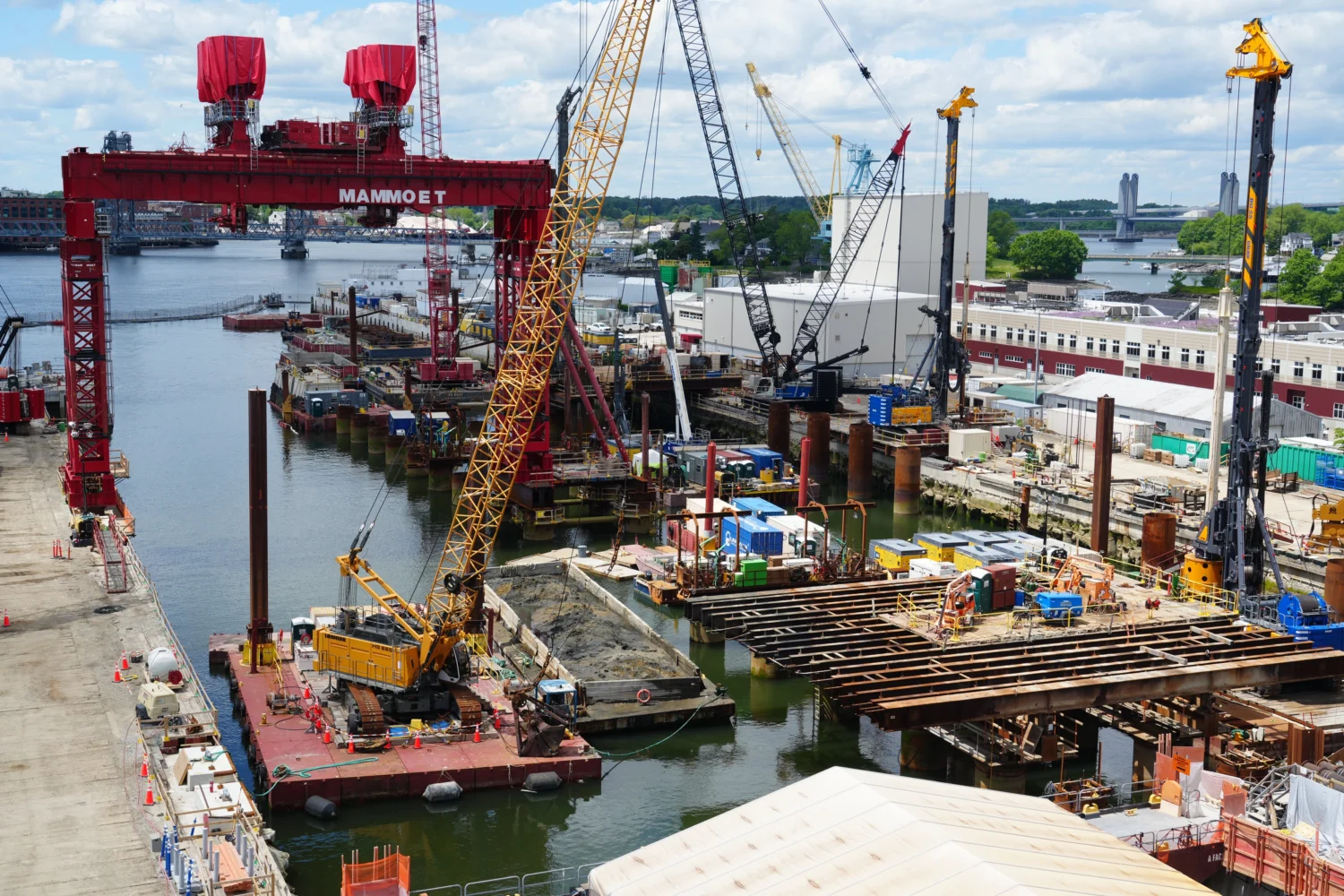

The Middlesex Corporation, as part of a joint venture with The Industrial Company and Cianbro Corporation, is constructing two new drydocks at the historic Portsmouth Naval Shipyard in Kittery, Maine.

The work is being performed within the Controlled Industrial Area, the most secure area on the base where there are numerous constraints and continuous impacts to the work. The drydocks will house U.S. Navy submarines during their retrofit, repairs, and refueling.

Each dock is approximately 525’ x 100’. 27 precast segments, weighing up to 5,000 tons, will be cast at our casting facility in Brewer, Maine. This site has a skid system that will use hydraulic jacks to move each segment to a specially built pier and gantry system, both engineered to handle the large segments. The segments will be loaded to custom-built barges and transported along the coast to the shipyard, where they will be set on 9’ diameter drilled shafts. Once set, 25,000 cy of tremie concrete will be placed to seal all joints and allow dewatering of the drydocks, and completion of the balance of the drydock walls.

The dewatering, electrical, and mechanicals systems are housed in the pump house and utility buildings, which will be constructed on top of the newly constructed dry dock.

By the Numbers

200K CY

Cast-in-Place Concrete

50K T

Reinforcing Steel

150

9′ Drilled Shafts

4.5K T per segment, 27 EA

Cast, Transport, & Set Drydock Segments

2

Entrance Structure Caissons

1.3K FT

Secant & Tangent Pile Support of Excavation

400

Peak Workforce

$1.1B

Project Value

Scope of Work

- Construct two new drydocks adjacent to an operational existing drydock, for repairs, retrofit, and refueling of U.S. Navy nuclear submarines

- New utility building and pump house associated with the operation of the drydock

- Remove existing utilities and construct new drainage, water, sewer, steam, and electrical systems

- Install temporary sheet pile, secant, and tangent wall support of excavation systems

Unique Challenges

- All work at the site is being performed within the Controlled Industrial Area (CIA). The access constraints are significant and impact how and when work can be performed.

- Working adjacent to an active drydock and the coordination of work with the submarine repair schedule.

- Constructing new drydocks adjacent to existing stacked stone berth walls while maintaining their integrity.

- Casting, transporting, and setting 27 precast segments weighing up to 5,000 tons.

- The Piscataqua River, the waterway where the work is taking place, is one of the most challenging and fast-moving waterways on the East Coast.

Copyright ©2025